In conventional reservoirs like sandstones and carbonates, decades of laboratory testing aided with field observations and history-matching, have shown good correlations between laboratory reservoir simulated tests and in-situ behavior. With unconventional shale reservoirs, laboratory tests are more challenging and need to be addressed.

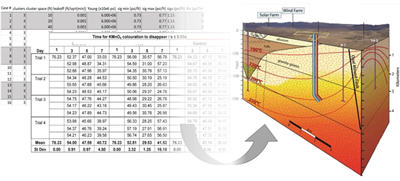

Overall, the usual objective for the oil/gas industry laboratory rock testing programs has been to gather a set of values that bracket the range of expected in-situ properties. In some cases, the testing program may be as simple as to gather a property "index" representation, at an estimated reservoir simulated condition, to compare with other rock measured properties. Where time and costs are major limitations, reservoir simulation may not be made at all, particularly when the results can be scaled to certain boundary constraints. For the latter, the aim may simply be to measure quantities that could correlate with other measurement techniques--such as seismic and/or wireline logs, and then use these inferred properties, together with petrophysical properties, as inputs to analytical and numerical in-situ simulation models.

In all the cases, the meaningfulness, usefulness, and the value of the laboratory measured rock properties could be assessed based on three quality control (QC) criteria:

Repeatability of tests,

Ability to correlate with other measurements,

Ability to scale, spatially and as inputs to models of wells and reservoirs.

For repeatability, the measured properties for a given lithologic unit should fall into a 'tight' statistical bell curve. For the correlation with other measurements, a cross-check of core ultrasonic to log sonic velocities, the dynamic versus the static properties, the unconfined compressive strength to moduli are compared with petrophysical properties like porosity, permeability, and mineralogy. Comparing with the equivalent wireline log values using scatter x-plots and log-plots are handy graphic correlations. And ultimately, the laboratory results are scaled to wellbore or reservoir scale, by using the laboratory measured properties in simulator models--such as drilling, wellbore stability, subsidence, sand production, hydraulic fracturing and production simulations.

For the unconventional reservoir rocks, like shales, complexity is magnified making laboratory testing more demanding. They contain sub-micron multi-mineral components, large quantities of platy clays, organic matter, micro- to nano-meter porosity, and complex multi-phase in-situ pore fluids. On the macro scale, the rocks contain fine layers and sub-parallel interfaces, natural fractures and inclusions. The rocks tend to be highly anisotropic with nano-Darcy matrix permeability, and thinly-layered rock fabric, leading to heterogeneity at all scales.

Generally, typical conventional types of tests are performed across all rock types, shales, sandstones, and carbonates alike; including the same reservoir simulation procedures--basically confine the sample to the estimated reservoir and pore pressure stresses and sometimes to reservoir temperatures. As with conventional samples, linear elastic properties are inferred as for sandstones and carbonates--Young's modulus, Poisson's ratio, unconfined compressive strength, ultrasonic velocities, etc. And the three QC criteria of repeatability, ability to correlate with other measurements, and scalability, are also applied,

Even cognizant of the elements that distinguish shales, simulating reservoir conditions in laboratory tests haven't changed significantly. However, the rock testing programs have become more intensive and more tests are conducted, leading to higher costs. Large test-specimens and bigger test-populations are desired. Shales are very fragile, with large sample to sample variability, with high plugging failure rates, leading to higher degrees of sampling bias where more fragile specimens are eliminated from the testing matrix.

Because of the extremely low permeability of the shales, pore pressure equilibration during the test is difficult to impossible to achieve. To help ensure reliable and repeatable tests, longer test-periods (i.e. slower loading rates) are conducted. Rock creep trends to a patchy pore pressure distribution, particularly for the higher clay samples. Some cases require "live" pore fluids, making re-saturation more complicated.

Cross-correlations of mechanical properties (like Young's modulus, Poisson’s ratio) with other petrophysical properties show a mix of test scatter and intrinsic rock variability, all due to heterogeneity. Statistically trends of frequency scatter plots and cross plots of these mechanical properties, and of petrophysical properties (such as micro-porosity and nano-Darcy permeability), are widely dispersed with high standard deviations and low correlation coefficients. Special techniques like continuous core profiling, CT and micro-CT, penetrometers, rebound testing, and continuous core logging, have proven their usefulness in characterization and correlations. However, keep in mind that these measurements are on un-stressed samples at ambient conditions.